A special thank you to Mike Anhalt of "On the Lam". If you need a rebuild look no further. Hire Mike. You can find him through the Lambretta Club USA.

Sunday, April 3, 2016

Bike is complete

As posted on Lambretta Club USA in the "Show us your Lambretta" forum titled "1962 TV175 S3 (pre-mod) resto". Click here to see.

Please note that this a "modern restoration" to create a beautiful daily rider. Anoraks will not be impressed.

Below I copied and pasted what I posted on LCUSA. I apologize in advance, because as a blogger, this is the absolute worst way to post this information. Each date below should have its own entry, but life has gotten the best of me and I have not posted in almost a year and I have now had the bike for a super long time. Maybe someday in the future I will break up this post as it should be.

Posted 31 March 2015 - 01:44 AM

About a decade ago I bought a TV175 S3 in a box. Much of it was there, but a few items took me years to find and acquire as I was new the Lambretta world. But once my network began to grow so many of you helped me out. I am truly indebted to LCUSA and can't express my thanks enough.

Life happened . . . career change, child #1 born, bi-coastal move, child #2 born and the only scooter completed was the 1967 SS180 I restored for my wife. Two working parents with kids . . . something had to give. I set a goal to have this bike complete and back on the road by the time I turned 40. I realized I needed to make a decision and that was is it more important to have bragging rights that I built my bike or to ride it. I chose to ride it. I hired Josh Snow to paint my bike and Mike Anhalt to build it.

This is how it began:

1962 Lambretta TV175 by jeremyjsutton, on Flickr

1962 Lambretta TV175 by jeremyjsutton, on Flickr

(yes one of the benefits to this buy was it came with two TV175 cases)

There were some piece meal parts.

1962 Lambretta TV175 in parts 2/3 by jeremyjsutton, on Flickr

1962 Lambretta TV175 in parts 2/3 by jeremyjsutton, on Flickr

But most of the critical parts were there. The hardest one to find and buy was the complete disc brake.

1962 Lambretta TV175 in parts 1/3 by jeremyjsutton, on Flickr

1962 Lambretta TV175 in parts 1/3 by jeremyjsutton, on Flickr

I would have been open to preserving the paint and keeping the stickers, but the parts were mismatched in paint. Looking back, I wish I had known about the option to scan and reproduce the original stickers. That would have been cool. I like details like that.

And now it looks something like this:

TV175 S3 resto by jeremyjsutton, on Flickr

TV175 S3 resto by jeremyjsutton, on Flickr

I am replacing the UNI Big Bore with an OEM Tutto pipe. The top-end is still 100% stock.

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr

(Will rotate the shock so the Indian logo does not show)

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr

It's no anorak's bike with an R6 shock, BGM ignition, Indian front shocks, and SS hardware, but there has been a lot of investment in details to give it the period correct look. I asked Josh and Mike for a beautiful daily rider and I believe I have gotten so much more than that.

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr

Correctly stamped hardware for seat:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

An earlier in the process shot not included above:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

A very special thanks to Mike and Josh. I am a bit anal and a micro manager at times, but I hired these guys so I wouldn't need to be nor worry. And hiring them was the smartest thing I did! This hire has saved me hours of stress, because I trust these guys completely.

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr

I would like to thank Stu for selling it to me, Gene M., Mark & Jon at Jet200, Tom G., and Paul Sachelari for so much advise along the way. And thank you Rudy Perez and Harmik for being my sounding board time and time again. You two have steered me right time and time again.

This is an early 1962 bike so I went with the "Coral Red" two tone.

History of the bike can be read here.

More . . . follow-up post.

Posted 04 April 2015 - 10:09 PM

Correctly stamped hardware for seat:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

An earlier in the process shot not included above:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

More . . . follow-up post.

Posted 04 April 2015 - 10:19 PM

Like all restorations, especially bike in a box ones, loads of obstacles came up along the way.

Coral Red:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Legshield needs some weld work and attention:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

For painter Josh Snow . . . a house move resulted in the loss of his paint booth. So he rented one. Fisheye in the paint due a car detail company next door with folks spraying the wheels with Armoral and into the paint it went. Josh sanded and rented again, but now dust.

So as my dad always says . . . if you want something done right do it yourself. Josh follows that mantra too. He built a small booth he can dismantle and store when not in use to finish up my paint job.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

More to follow. This bike has a bit of story to get it back to its original glory (well semi close considering it was not a complete bike). A lot of blood, sweat, and tears have gone into this build from multiple people. The soul of this scooter is being honored.

To see a really cool story about this bike . . . see how a jacked up, cracked up, ripped fiberglass fender was saved -- all for a $30 bottle of wine. Click here to read that story.

More . . . follow-up post.

Posted 28 April 2015 - 01:29 AM

Coral red clear coated:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

Thanks Josh Snow.

More . . . follow-up post.

Finally tracked down the correct set of control rods . . . Thanks G (& Rudy)!

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

These proved challenging for me to find over the years. The repop set I received from Scooter Restorations were not made correctly.

Dang problem with buying a bike in a box is hunting down parts.

Good news . . . Mike Anhalt said the bike fired up after the 3rd kick and it sounded great. He sent me a video.

For all the "smalls" and "technical considerations" with this specific build damn I am lucky to have Mike on the job. He has super high standards. I would have missed some of this stuff due to my lack of experience. I am learning so much from Mike -- a true mentor. He and Tom G. have been the best scootering resources for me without a doubt.

Josh Snow's standards are freakin' up there too. He has taught me quite a bit about the painting process.

So what's left?

More . . . follow-up post.

I think the fork bend was 1/8" off:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

I was upset when I learned that since it had just been painted, but Dean minimized damage to paint to only where it could not be seen:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

I remind myself it could have been worse. Mike Anhalt touched up with paint the hidden part of the fork so it will not rust and away it went.

Beyond that challenge (and more) is the fact that when the seller sold me the bike be showed me original TV forks that his machinist unknowingly destroyed beyond repair. So he a had a pair of Li forks (fortunately they are pre-mod style to match the bike per Stickey) and had his welder weld the front dampener bracket on it. Josh Snow tested it for resistance and it met spec for strength.

However, the problem is where the brackets were mounted (height wise good, but a hair off horizontally), resulting in maybe a shorter life for the plastic bushings, but Mike said they will still function as intended.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

As Mike said, a project indeed. I will post more later.

More . . . follow-up post.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

The funny thing is the seller had to sets laid out when I bought the bike-in-a-box and he accidentally gave me two left links. I contacted him and he sold me both right side ones to choose what I wanted. Very fair. I selected the set branded "Innocenti". I guess the others are Casa repops or something. I had concerns about the grooves, but they were both shaped with a similar grove, so foolishly I kept them.

Mike had his machinist fill in the hole and prep new holes. Mike told me they would be as good as new when done.

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr

The chrome chipped, but the links were solid once more. I did not have them re-chromed. I could, but the exposed areas cleaned up well. So I have an original set that has been repaired and is ready for riding.

More . . . follow-up post.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Mike Anhalt added frame supports:

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

It's these littles that come second nature to Mike and I may or may not have caught if I had built the bike. My wife said this weekend that she was really happy Mike was building the bike too, because of his attention to detail combined with his experience and know-how.

Unfortunately, though Lammy Jammy is in my own state, the bike won't be there as I planned a family trip abroad nearly two years ago. So I aiming to pick up the finished product in mid-July. So so close.

Update from Josh Snow is there is one more part needs a clear coat and some sanding and buffing and then the final pieces leave his garage.

On May 11th my muffler, u-bend, and clip will be mailed back to Mike from the ceramic coater. I will post a review of the quality of work and price I paid if the quality is great.

I can't wait to ride it!

More . . . follow-up post.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

And now installed on the bike:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

All that is left is the sheet metal with Josh Snow is finishing up.

More . . . follow-up post.

Prior to having the muffler ceramic coated Mike had the pipe/clamp welded for a true stock look:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

More . . . follow-up post.

More . . . follow-up post.

Fortunately, Mike is a veteran and relaxed and chilled and proactive in problem-solving.

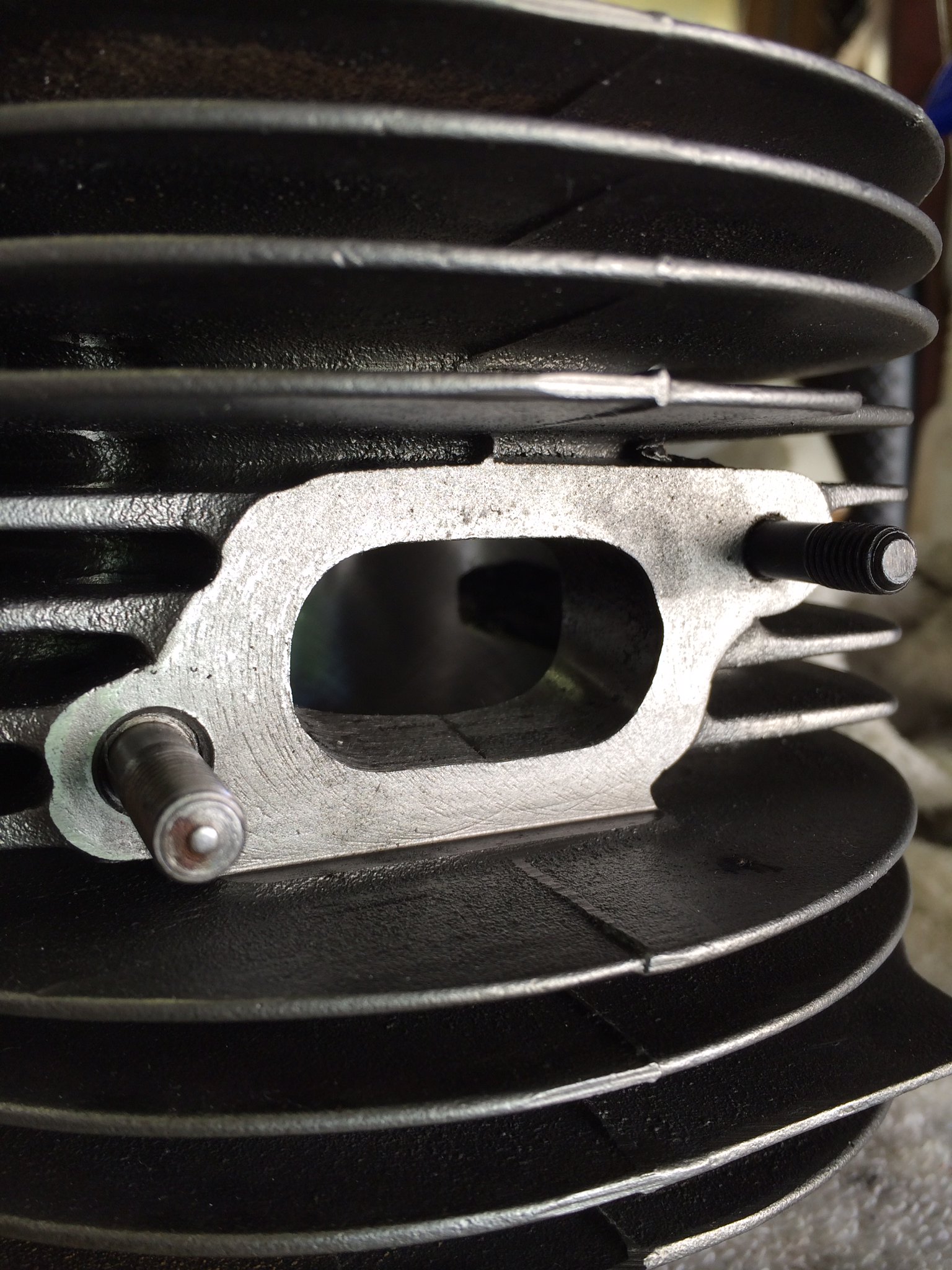

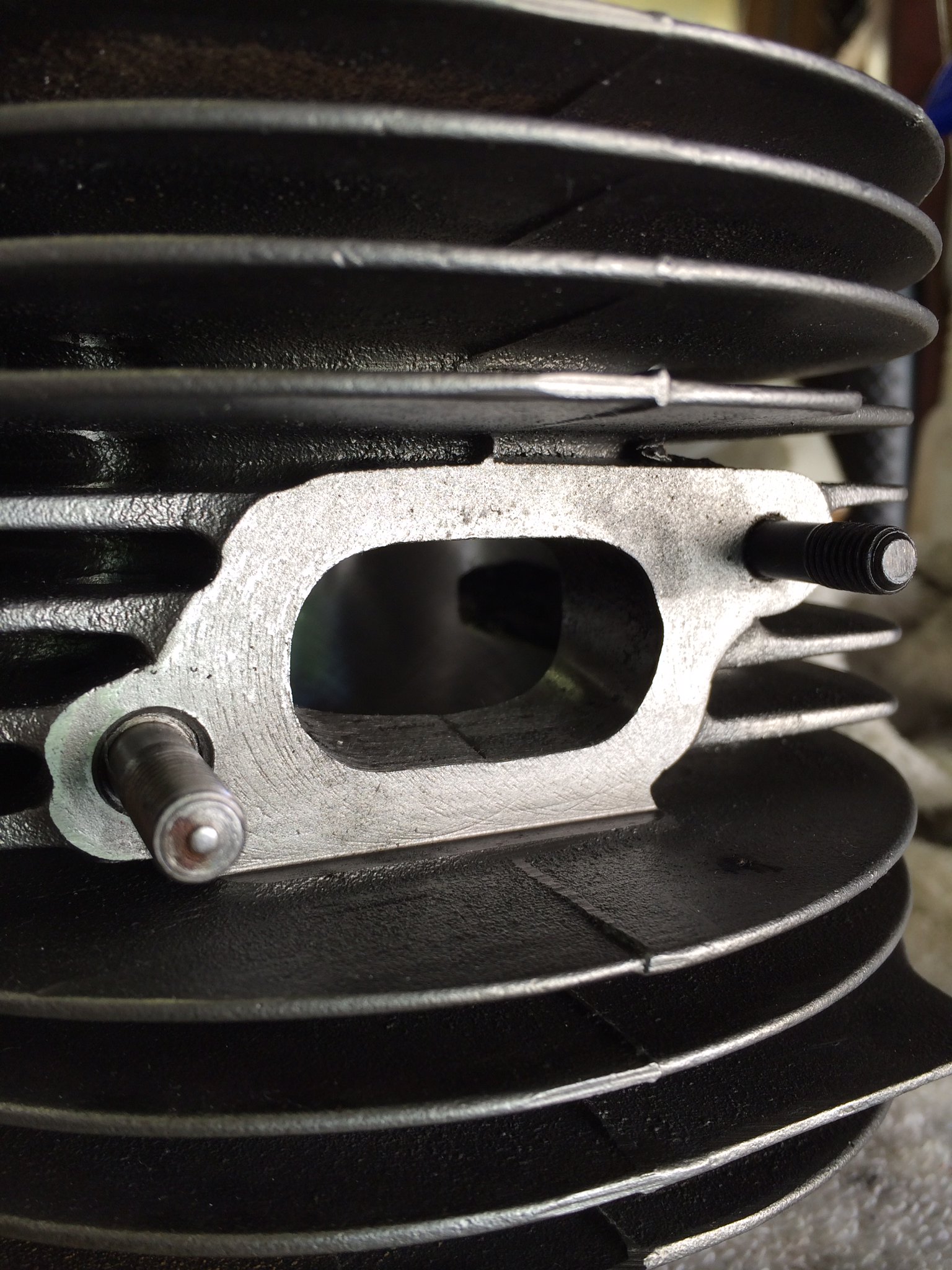

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Look very very closely at those threads. See anything usual?

Yep, someone stuffed a larger diameter bolt in the head instead of doing it right and having it repaired. Mike ordered the correct size threaded bolt and had his machinist repair it.

Of course, I had to go (I believe) 2 over to have the piston re-bored and meet Mike's standards.

He then high-temp painted it for stock look.

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

The end product is damn nice.

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

This is where that "but wait for $19,99 there is even YET more" . . .

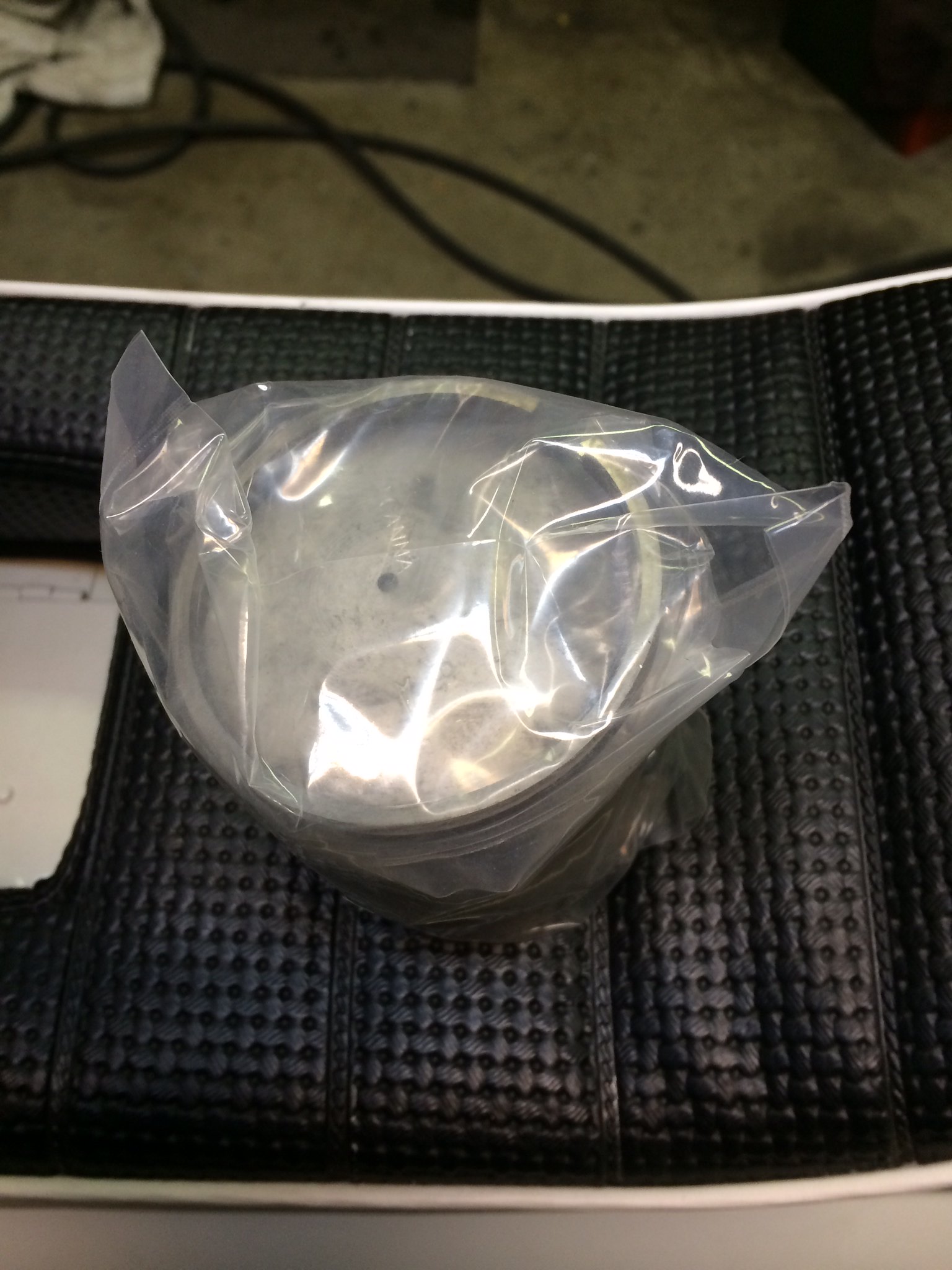

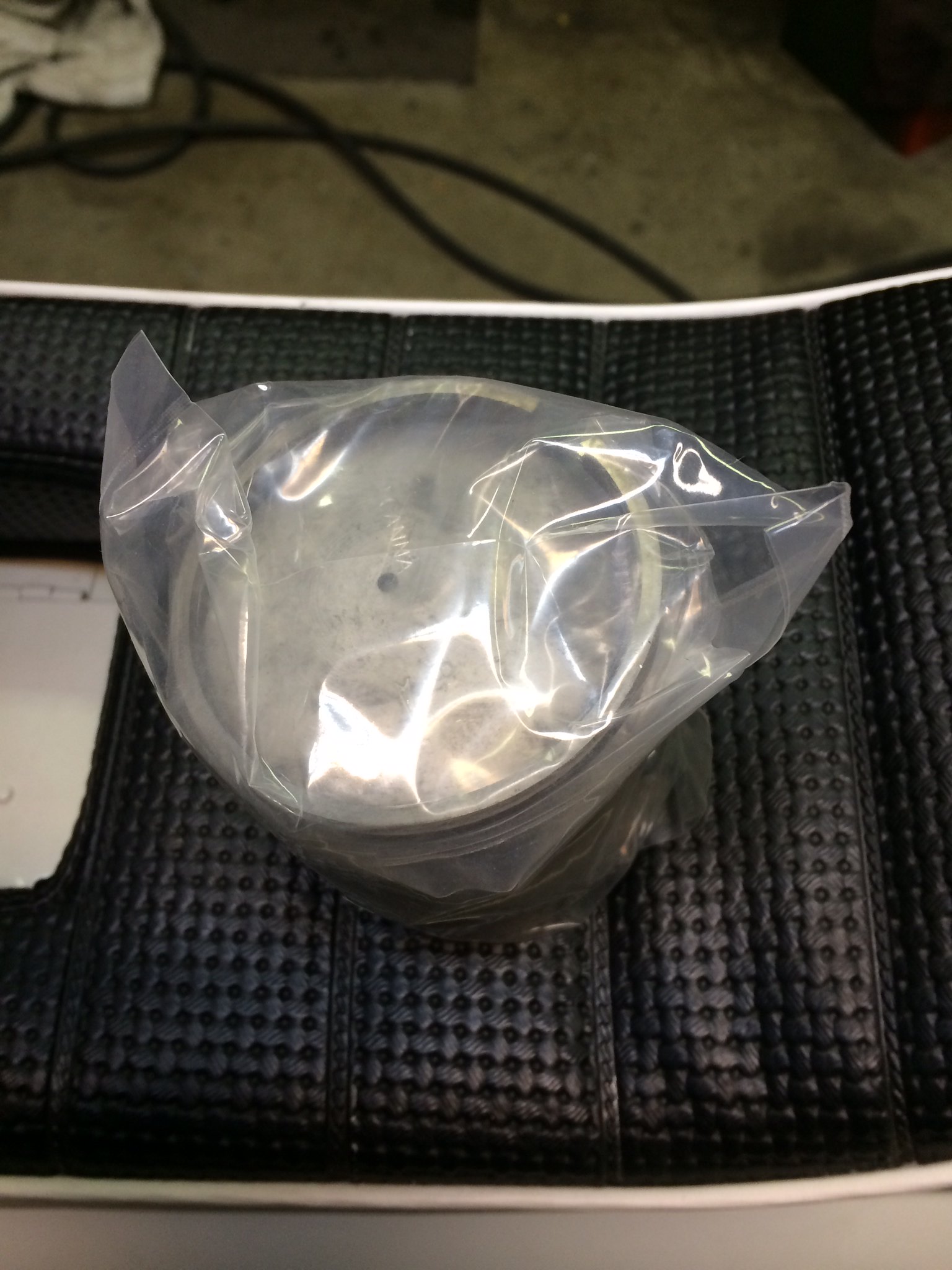

We couldn't find a piston forever. Ordered abroad. Took 2 months to arrive due to post. Damaged in transit. Damnit!!!!

Luckily, thanx for Mark and Jon at Jet200 I found an NOS piston and bought that bastard so freakin' fast!

Untitled by jeremyjsutton, on Flickr

62.8 Mondial NOS piston

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

This build feels like a freakin' wedding. With my bride (of 13 years) we set a budget and I remember watching it slip and slip some more and slip some more - I got frustrated. It caused tension. However it's the best god damn party I ever went to and I would do it again in a heart beat. Hell I'd throw another $10K at it if I could (that's a pipe dream). So if I feel half as good as my wedding day when I test ride this bike I won't think twice about the frustrations and cash gone (and my girl and I predict I will fall in love my bike right away).

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr

I am an Lit teacher and teach American Lit to 11th graders. My standards push insanity, ie write a 2-page essay (that is so hard to do because it should be a 4 page essay -- students must cut all good evidence and analysis and only keep the excellent) on Faulker's use of 3 literary devices to illustrate Darl's decent into madness and then connect it to his social commentary. I know what I do for living. Mike does too with his Lammy builds. And when it comes to builds I am so damn happy I hired Mike. I take my job beyond seriously and it is evident that Mike does too. He is pro!

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr

Thank you Mike. This moment is for you!

More . . . follow-up post.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

It should also be noted that this bike-in-a-box build was not easy on the painter either.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Like Mike, Josh Snow powered through it.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

As I said before, I asked for a beautiful daily rider and that's what I got.

I am very happy with Josh's eye for catching the small things. These parts look awesome!

The Coral Red was matched from the "Lambretta Paint Book: 1962" paint chips. Josh had the color matched.

More . . . follow-up post.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

My glove box lock was gummed up good, but Mike was able to clean and polish.

More . . . follow-up post.

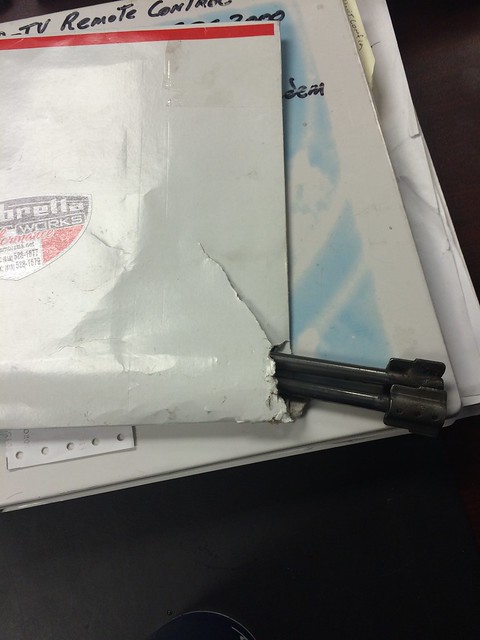

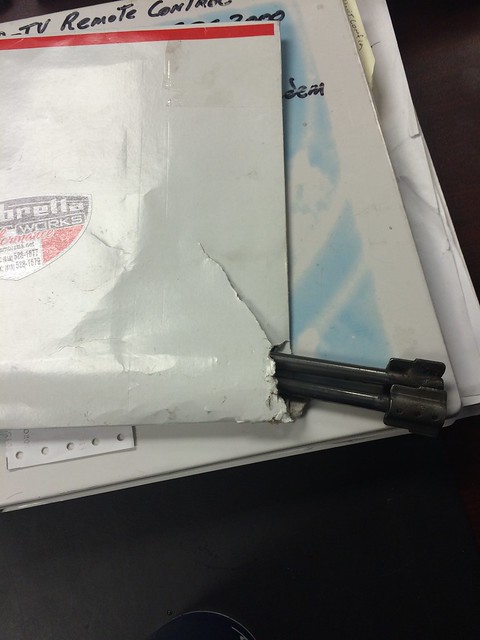

I spent some good time over the years looking for TV control rods (which are shorter than Li), but had no luck. Barry G. found a pair, but one was damaged. After having no luck in my search and needing to keep my build going with Mike, I opted for buying the repops from Scooter Restorations in the UK.

The set I received was made wrong.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

The paddle was welded wrong relative to the rod. (I posted this in the "Product Review" section as well as it seemed appropriate).

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Rudy P. checked in with me after I lucked out with the repops and gave me suggestions on other places to check.

I finally found and bought a set from Lambretta Works.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

This is how the original Innocenti set arrived to Mike Anhalt. Damn near got lost in the mail. Thanks to G for having them and polishing them up for me prior to mailing.

These two parts slowed the build down and had Mike at a stand still for a while.

More . . . follow-up post.

Just found this photo in my Face Book photos -- I had totally forgotten about it.

Lambretta_TV175_PartsInBox by jeremyjsutton, on Flickr

Lambretta_TV175_PartsInBox by jeremyjsutton, on Flickr

Josh gave me something totally opposite in return.

My batch-o-parts was truly a hodgepodge.

More . . . follow-up post.

IMG_2309 by je

IMG_2309 by je

More . . . follow-up post.

Mike polished out the side panel levers, which were in pretty bad shape with deep scratches. A major improvement.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

This photo was taken just prior to clean up and polishing out. Nice detail - that's Mike for you. All the "smalls" he does on his builds.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

More . . . follow-up post.

It is "butter" to ride. Love it. Mike Anhalt and Josh Snow make me look good!

Home with me now. Breaking it in.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Original Italian speedo (calls to history and soul of bike)

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

A few hidden spots to call history of bike(s) lived. Many of you members have provided parts on this bike. And now all of you are part of soul of this bike. Maybe I am cheesy or Hallmark, but that's important to me.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Some anorak details:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Original:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

I am just smitten:

Untitled by jeremyjsutton, on Flickr

As Brandon replied to my statement, "damn this bike fought me every step of the way" he said "that's Lambretta. You gotta be indoctrinated into this." Indeed he was correct.

My P200 is named after my maternal grandmother and I am working on a name to incorporate my paternal grandmother for this Lammy.

Now, I need to ride . . .

More . . . follow-up post.

On the road and loving it!

Finished by jeremyjsutton, on Flickr

Finished by jeremyjsutton, on Flickr

Titled, registered, and licensed. Waiving my LCUSA flag.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Thanks to BrooklynPete for the Lucas style plate holder. Had it powder coated to match.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Please note that this a "modern restoration" to create a beautiful daily rider. Anoraks will not be impressed.

Below I copied and pasted what I posted on LCUSA. I apologize in advance, because as a blogger, this is the absolute worst way to post this information. Each date below should have its own entry, but life has gotten the best of me and I have not posted in almost a year and I have now had the bike for a super long time. Maybe someday in the future I will break up this post as it should be.

Posted 31 March 2015 - 01:44 AM

About a decade ago I bought a TV175 S3 in a box. Much of it was there, but a few items took me years to find and acquire as I was new the Lambretta world. But once my network began to grow so many of you helped me out. I am truly indebted to LCUSA and can't express my thanks enough.

Life happened . . . career change, child #1 born, bi-coastal move, child #2 born and the only scooter completed was the 1967 SS180 I restored for my wife. Two working parents with kids . . . something had to give. I set a goal to have this bike complete and back on the road by the time I turned 40. I realized I needed to make a decision and that was is it more important to have bragging rights that I built my bike or to ride it. I chose to ride it. I hired Josh Snow to paint my bike and Mike Anhalt to build it.

This is how it began:

1962 Lambretta TV175 by jeremyjsutton, on Flickr

1962 Lambretta TV175 by jeremyjsutton, on Flickr(yes one of the benefits to this buy was it came with two TV175 cases)

There were some piece meal parts.

1962 Lambretta TV175 in parts 2/3 by jeremyjsutton, on Flickr

1962 Lambretta TV175 in parts 2/3 by jeremyjsutton, on FlickrBut most of the critical parts were there. The hardest one to find and buy was the complete disc brake.

1962 Lambretta TV175 in parts 1/3 by jeremyjsutton, on Flickr

1962 Lambretta TV175 in parts 1/3 by jeremyjsutton, on FlickrI would have been open to preserving the paint and keeping the stickers, but the parts were mismatched in paint. Looking back, I wish I had known about the option to scan and reproduce the original stickers. That would have been cool. I like details like that.

And now it looks something like this:

TV175 S3 resto by jeremyjsutton, on Flickr

TV175 S3 resto by jeremyjsutton, on FlickrI am replacing the UNI Big Bore with an OEM Tutto pipe. The top-end is still 100% stock.

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr(Will rotate the shock so the Indian logo does not show)

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on FlickrIt's no anorak's bike with an R6 shock, BGM ignition, Indian front shocks, and SS hardware, but there has been a lot of investment in details to give it the period correct look. I asked Josh and Mike for a beautiful daily rider and I believe I have gotten so much more than that.

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on FlickrCorrectly stamped hardware for seat:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrAn earlier in the process shot not included above:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrA very special thanks to Mike and Josh. I am a bit anal and a micro manager at times, but I hired these guys so I wouldn't need to be nor worry. And hiring them was the smartest thing I did! This hire has saved me hours of stress, because I trust these guys completely.

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on Flickr TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on FlickrI would like to thank Stu for selling it to me, Gene M., Mark & Jon at Jet200, Tom G., and Paul Sachelari for so much advise along the way. And thank you Rudy Perez and Harmik for being my sounding board time and time again. You two have steered me right time and time again.

This is an early 1962 bike so I went with the "Coral Red" two tone.

History of the bike can be read here.

More . . . follow-up post.

Posted 04 April 2015 - 10:09 PM

Correctly stamped hardware for seat:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrAn earlier in the process shot not included above:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrMore . . . follow-up post.

Posted 04 April 2015 - 10:19 PM

Like all restorations, especially bike in a box ones, loads of obstacles came up along the way.

Coral Red:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrLegshield needs some weld work and attention:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrFor painter Josh Snow . . . a house move resulted in the loss of his paint booth. So he rented one. Fisheye in the paint due a car detail company next door with folks spraying the wheels with Armoral and into the paint it went. Josh sanded and rented again, but now dust.

So as my dad always says . . . if you want something done right do it yourself. Josh follows that mantra too. He built a small booth he can dismantle and store when not in use to finish up my paint job.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrMore to follow. This bike has a bit of story to get it back to its original glory (well semi close considering it was not a complete bike). A lot of blood, sweat, and tears have gone into this build from multiple people. The soul of this scooter is being honored.

To see a really cool story about this bike . . . see how a jacked up, cracked up, ripped fiberglass fender was saved -- all for a $30 bottle of wine. Click here to read that story.

More . . . follow-up post.

Posted 28 April 2015 - 01:29 AM

Coral red clear coated:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr by jeremyjsutton, on Flickr

by jeremyjsutton, on FlickrThanks Josh Snow.

More . . . follow-up post.

Posted 29 April 2015 - 01:43 AM

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrThese proved challenging for me to find over the years. The repop set I received from Scooter Restorations were not made correctly.

Dang problem with buying a bike in a box is hunting down parts.

Good news . . . Mike Anhalt said the bike fired up after the 3rd kick and it sounded great. He sent me a video.

For all the "smalls" and "technical considerations" with this specific build damn I am lucky to have Mike on the job. He has super high standards. I would have missed some of this stuff due to my lack of experience. I am learning so much from Mike -- a true mentor. He and Tom G. have been the best scootering resources for me without a doubt.

Josh Snow's standards are freakin' up there too. He has taught me quite a bit about the painting process.

So what's left?

Attach pulleys/cables

Install headset lock

Install ignition switch

Wire headset

Install headlight

Install headset top with speedometer

Connect rear brake cable and adjust

Cylinder tin

Install exhaust after back from ceramic paint

Buy key 217 for glove box

Clear coat horncast

Install sheet metal parts

etc.

More . . . follow-up post.

Posted 01 May 2015 - 04:14 PM

Yah PDX Mike . . . as Mike Anhalt said this has been a project.I think the fork bend was 1/8" off:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrI was upset when I learned that since it had just been painted, but Dean minimized damage to paint to only where it could not be seen:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrI remind myself it could have been worse. Mike Anhalt touched up with paint the hidden part of the fork so it will not rust and away it went.

Beyond that challenge (and more) is the fact that when the seller sold me the bike be showed me original TV forks that his machinist unknowingly destroyed beyond repair. So he a had a pair of Li forks (fortunately they are pre-mod style to match the bike per Stickey) and had his welder weld the front dampener bracket on it. Josh Snow tested it for resistance and it met spec for strength.

However, the problem is where the brackets were mounted (height wise good, but a hair off horizontally), resulting in maybe a shorter life for the plastic bushings, but Mike said they will still function as intended.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrAs Mike said, a project indeed. I will post more later.

More . . . follow-up post.

Posted 01 May 2015 - 10:25 PM

Another challenge was finding replacement TV fork links, because

mine had been ridden about 10K miles after the plastic bushings had

worn out and it resulted in two terrible groves in them. Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrThe funny thing is the seller had to sets laid out when I bought the bike-in-a-box and he accidentally gave me two left links. I contacted him and he sold me both right side ones to choose what I wanted. Very fair. I selected the set branded "Innocenti". I guess the others are Casa repops or something. I had concerns about the grooves, but they were both shaped with a similar grove, so foolishly I kept them.

Mike had his machinist fill in the hole and prep new holes. Mike told me they would be as good as new when done.

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on FlickrThe chrome chipped, but the links were solid once more. I did not have them re-chromed. I could, but the exposed areas cleaned up well. So I have an original set that has been repaired and is ready for riding.

More . . . follow-up post.

Posted 04 May 2015 - 04:26 PM

Electrical tested and working Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrMike Anhalt added frame supports:

by jeremyjsutton, on Flickr

by jeremyjsutton, on FlickrIt's these littles that come second nature to Mike and I may or may not have caught if I had built the bike. My wife said this weekend that she was really happy Mike was building the bike too, because of his attention to detail combined with his experience and know-how.

Unfortunately, though Lammy Jammy is in my own state, the bike won't be there as I planned a family trip abroad nearly two years ago. So I aiming to pick up the finished product in mid-July. So so close.

Update from Josh Snow is there is one more part needs a clear coat and some sanding and buffing and then the final pieces leave his garage.

On May 11th my muffler, u-bend, and clip will be mailed back to Mike from the ceramic coater. I will post a review of the quality of work and price I paid if the quality is great.

I can't wait to ride it!

More . . . follow-up post.

Posted 16 May 2015 - 08:12 PM

Pipe is back from painter with fresh coat of ceramic on it. Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrAnd now installed on the bike:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrAll that is left is the sheet metal with Josh Snow is finishing up.

More . . . follow-up post.

Prior to having the muffler ceramic coated Mike had the pipe/clamp welded for a true stock look:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrMore . . . follow-up post.

Posted 16 May 2015 - 09:14 PM

As Mike and I both said, building a bike in a box project is not ideal and poses challenges.

One challenge was the carb body.

Finding a carb body without stripped threads was not so easy nor quick.

I bought this one and was told that I could file the mouth down smooth for function.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

So I checked the threads and they seemed good. I bought the complete carb for $75. Then I paid Peter to vapor blast it.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Mike is very particular about his standards during a build (which is why I hired him and would do it again in a heart beat). He tried to repair the carb body, but to no avail. He wanted a carb in the best possible condition so the bike can run strong and healthy stock.

Hunting down the new body was not as quick as we would have liked.

Rudy Perez was generous enough to hook me up with a happy and healthier carb body. Mike suggested not to have it vapor blasted and to just clean it up for a truer to stock look.

Here it is . . .

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Thank you Rudy!

One challenge was the carb body.

Finding a carb body without stripped threads was not so easy nor quick.

I bought this one and was told that I could file the mouth down smooth for function.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrSo I checked the threads and they seemed good. I bought the complete carb for $75. Then I paid Peter to vapor blast it.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrMike is very particular about his standards during a build (which is why I hired him and would do it again in a heart beat). He tried to repair the carb body, but to no avail. He wanted a carb in the best possible condition so the bike can run strong and healthy stock.

Hunting down the new body was not as quick as we would have liked.

Rudy Perez was generous enough to hook me up with a happy and healthier carb body. Mike suggested not to have it vapor blasted and to just clean it up for a truer to stock look.

Here it is . . .

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrThank you Rudy!

Posted 16 May 2015 - 10:03 PM

But wait, for $19.99 there is more . . . building this bike has

felt like a info-merricial that identifies more and more issues that

must be resolved. Translation: my wallet gets thinner with every

discovery and Mike has added time to work and worse added down time

waiting for parts.Fortunately, Mike is a veteran and relaxed and chilled and proactive in problem-solving.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrLook very very closely at those threads. See anything usual?

Yep, someone stuffed a larger diameter bolt in the head instead of doing it right and having it repaired. Mike ordered the correct size threaded bolt and had his machinist repair it.

Of course, I had to go (I believe) 2 over to have the piston re-bored and meet Mike's standards.

He then high-temp painted it for stock look.

by jeremyjsutton, on Flickr

by jeremyjsutton, on FlickrThe end product is damn nice.

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr by jeremyjsutton, on Flickr

by jeremyjsutton, on FlickrThis is where that "but wait for $19,99 there is even YET more" . . .

We couldn't find a piston forever. Ordered abroad. Took 2 months to arrive due to post. Damaged in transit. Damnit!!!!

Luckily, thanx for Mark and Jon at Jet200 I found an NOS piston and bought that bastard so freakin' fast!

Untitled by jeremyjsutton, on Flickr

62.8 Mondial NOS piston

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickrby jeremyjsutton, on Flickr

This build feels like a freakin' wedding. With my bride (of 13 years) we set a budget and I remember watching it slip and slip some more and slip some more - I got frustrated. It caused tension. However it's the best god damn party I ever went to and I would do it again in a heart beat. Hell I'd throw another $10K at it if I could (that's a pipe dream). So if I feel half as good as my wedding day when I test ride this bike I won't think twice about the frustrations and cash gone (and my girl and I predict I will fall in love my bike right away).

by jeremyjsutton, on Flickr

by jeremyjsutton, on Flickr by jeremyjsutton, on Flickr

by jeremyjsutton, on FlickrI am an Lit teacher and teach American Lit to 11th graders. My standards push insanity, ie write a 2-page essay (that is so hard to do because it should be a 4 page essay -- students must cut all good evidence and analysis and only keep the excellent) on Faulker's use of 3 literary devices to illustrate Darl's decent into madness and then connect it to his social commentary. I know what I do for living. Mike does too with his Lammy builds. And when it comes to builds I am so damn happy I hired Mike. I take my job beyond seriously and it is evident that Mike does too. He is pro!

TV175 S3 rest by jeremyjsutton, on Flickr

TV175 S3 rest by jeremyjsutton, on FlickrThank you Mike. This moment is for you!

More . . . follow-up post.

Posted 19 May 2015 - 03:41 AM

Sneak peak as paint is finished up. Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrIt should also be noted that this bike-in-a-box build was not easy on the painter either.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrLike Mike, Josh Snow powered through it.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrAs I said before, I asked for a beautiful daily rider and that's what I got.

I am very happy with Josh's eye for catching the small things. These parts look awesome!

The Coral Red was matched from the "Lambretta Paint Book: 1962" paint chips. Josh had the color matched.

More . . . follow-up post.

Posted 22 May 2015 - 02:47 PM

Glove box install. Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrMy glove box lock was gummed up good, but Mike was able to clean and polish.

More . . . follow-up post.

Posted 22 May 2015 - 02:54 PM

Yet another issue which slowed the build.I spent some good time over the years looking for TV control rods (which are shorter than Li), but had no luck. Barry G. found a pair, but one was damaged. After having no luck in my search and needing to keep my build going with Mike, I opted for buying the repops from Scooter Restorations in the UK.

The set I received was made wrong.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrThe paddle was welded wrong relative to the rod. (I posted this in the "Product Review" section as well as it seemed appropriate).

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrRudy P. checked in with me after I lucked out with the repops and gave me suggestions on other places to check.

I finally found and bought a set from Lambretta Works.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrThis is how the original Innocenti set arrived to Mike Anhalt. Damn near got lost in the mail. Thanks to G for having them and polishing them up for me prior to mailing.

These two parts slowed the build down and had Mike at a stand still for a while.

More . . . follow-up post.

Posted 23 May 2015 - 05:22 AM

When Josh Snow came over to my house to look at the project I had for him . . . this is exactly what he saw.Just found this photo in my Face Book photos -- I had totally forgotten about it.

Lambretta_TV175_PartsInBox by jeremyjsutton, on Flickr

Lambretta_TV175_PartsInBox by jeremyjsutton, on FlickrJosh gave me something totally opposite in return.

My batch-o-parts was truly a hodgepodge.

More . . . follow-up post.

Posted 23 May 2015 - 05:24 AM

The sound of a stock TV175 top-end with a stock pipe. IMG_2309 by je

IMG_2309 by je More . . . follow-up post.

Posted 18 June 2015 - 04:17 AM

Some more progress.Mike polished out the side panel levers, which were in pretty bad shape with deep scratches. A major improvement.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrThis photo was taken just prior to clean up and polishing out. Nice detail - that's Mike for you. All the "smalls" he does on his builds.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrMore . . . follow-up post.

Posted 28 July 2015 - 04:33 AM

Sorry I haven't washed yet. Just too excited to share.It is "butter" to ride. Love it. Mike Anhalt and Josh Snow make me look good!

Home with me now. Breaking it in.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrOriginal Italian speedo (calls to history and soul of bike)

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrA few hidden spots to call history of bike(s) lived. Many of you members have provided parts on this bike. And now all of you are part of soul of this bike. Maybe I am cheesy or Hallmark, but that's important to me.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrUntitled by jeremyjsutton, on Flickr

Some anorak details:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrOriginal:

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrI am just smitten:

Untitled by jeremyjsutton, on Flickr

As Brandon replied to my statement, "damn this bike fought me every step of the way" he said "that's Lambretta. You gotta be indoctrinated into this." Indeed he was correct.

My P200 is named after my maternal grandmother and I am working on a name to incorporate my paternal grandmother for this Lammy.

Now, I need to ride . . .

More . . . follow-up post.

On the road and loving it!

Finished by jeremyjsutton, on Flickr

Finished by jeremyjsutton, on FlickrTitled, registered, and licensed. Waiving my LCUSA flag.

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on FlickrThanks to BrooklynPete for the Lucas style plate holder. Had it powder coated to match.

Posted 05 September 2015 - 09:08 AM

Untitled by jeremyjsutton, on Flickr

Untitled by jeremyjsutton, on Flickr

Subscribe to:

Posts (Atom)